Hot Gas Component Repair & Overhaularrow_drop_down

Hot Gas Component Repair & Overhaul

Thermal Barrier Coating (TBC) technology is widely applied to high-temperature components in aircraft and gas turbine engines.

This coating system typically consists of a ceramic top coat with low thermal conductivity and a bond coat that enhances adhesion between the top coat and the substrate.

By optimizing the porosity of the top coat, TBC provides both low thermal conductivity and high strain tolerance,

effectively reducing the surface temperature of the base material by approximately 100 to 170°C compared to the flame temperature.

This significantly extends the operational lifespan of turbine components by mitigating thermal degradation.

* Hot gas part repair process : The hot gas part repair process involves refurbishing and restoring gas turbine hot-section components that have reached the end of their service life.

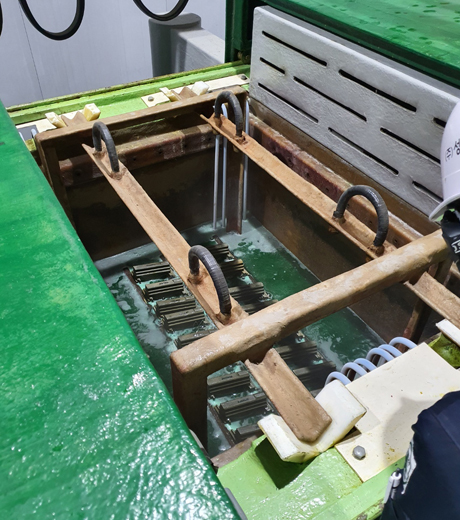

Cleaning of parts

Airflow test of blade and vane

Removal of Coating

Heat Tint Test after Chemical stripping

Fluorescent penetrant inspection

Heat treatment

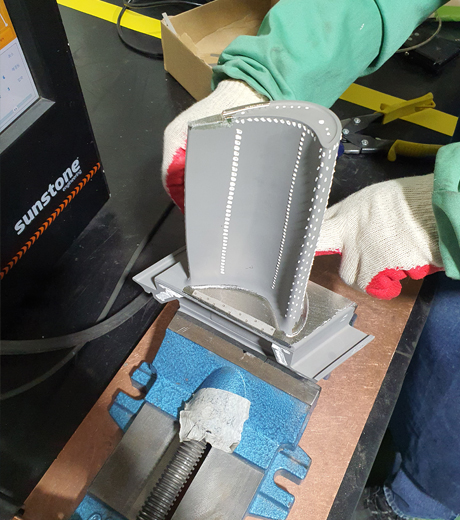

Welding, Blending

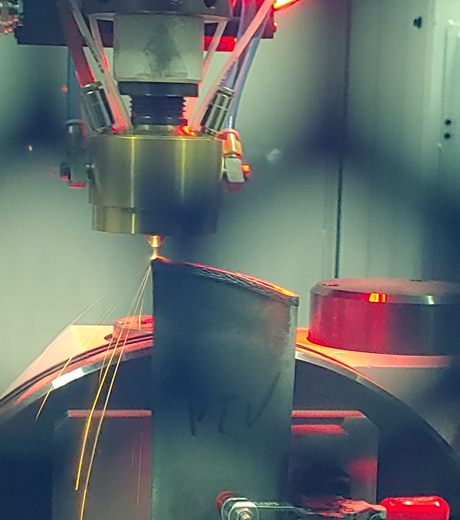

Laser Cladding

Brazing Repair

Heat treatment of solution

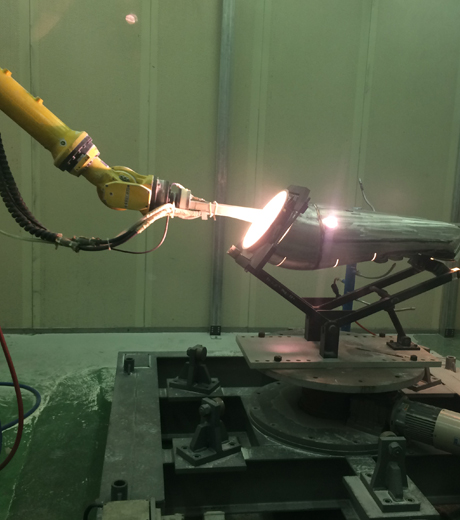

Thermal Barrier Coating

Assembly, Airflow,Dimensional Inspection