Vacuum Precision Castingarrow_drop_down

Vacuum Precision Casting

The vacuum precision casting process is conducted in a vacuum environment, effectively eliminating harmful gases such as hydrogen, oxygen, and nitrogen.

This ensures enhanced stability and superior product quality.

This process not only prevents the formation of impurities and inclusions in the final product by eliminating reactions between the molten metal

and atmospheric gases during the melting stage but also suppresses casting defects caused by moisture present in the ambient environment.

Furthermore, when casting alloys containing highly oxidizable elements, the vacuum environment minimizes alloying element loss,

thereby achieving the desired and stable alloy composition.

Due to its capability to produce complex and intricate geometries that are difficult to machine, vacuum precision casting is particularly suitable

for applications requiring high dimensional accuracy.

(This process is essential for manufacturing high-temperature components in gas turbines, as it enhances the mechanical properties

of the components while ensuring reliable performance under extreme operating conditions.)

Among various casting methods, precision casting offers unparalleled design flexibility, enabling the production of components with complex geometries and intricate details that may be challenging or impossible to achieve through conventional machining processes. Additionally, this method significantly reduces machining costs while facilitating high-volume production, making it an efficient and cost-effective manufacturing solution.

Wax Injection

Ceramic Core Leaching

Shell Coating

Dewaxing

Firing

Casting

Hot Isostatic Press

Machining

25-ton wax injection equipment

50-ton wax injection equipment

150-ton wax injection equipment

Ceramic Core Leaching

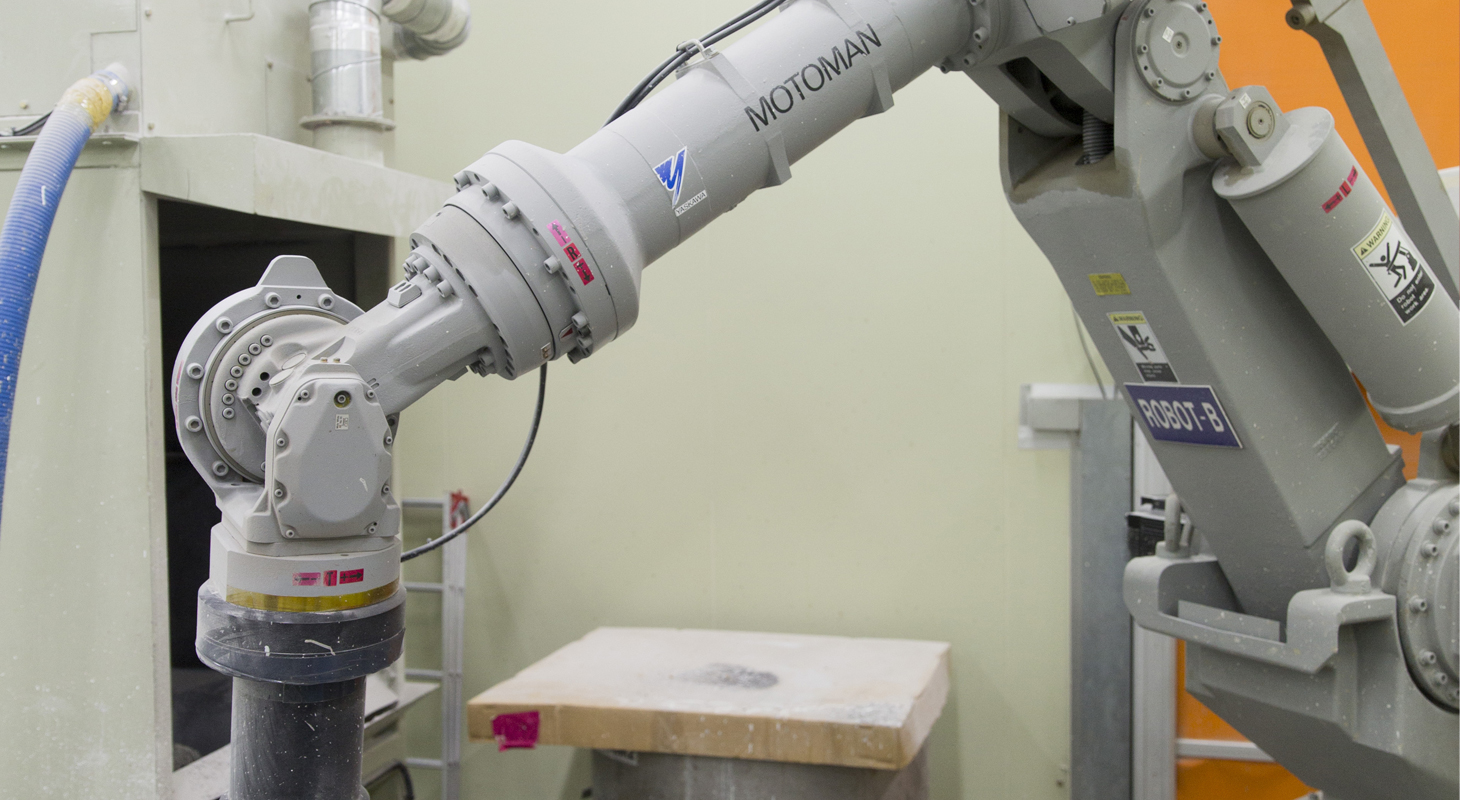

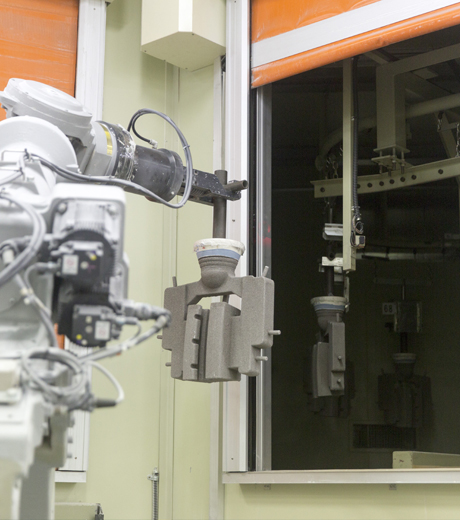

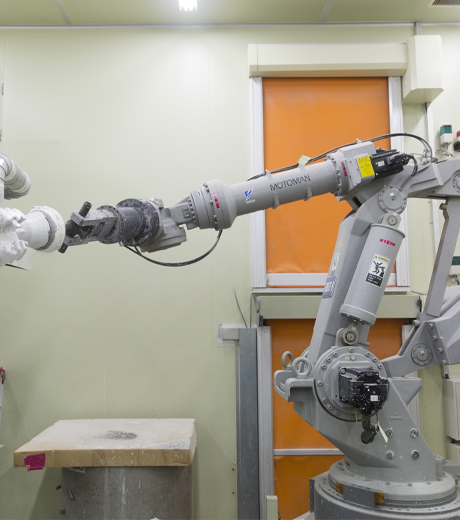

Slurry coating and Stuccoing System

Slurry coating and Stuccoing System

Slurry coating and Stuccoing System

Boiler Autoclave

Firing Burnout Furnace

Vacuum Precision Casting Furnace (50kg)

Vacuum Precision Casting Furnace (300kg)

Vacuum Precision Casting Furnace (80kg, SX/DS)

Hot Isostatic Press Furnace

Single Creep Feed Grinding

Super Drill